Surface Protection Treatment

Blackodizing (Black Oxide)

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys etc

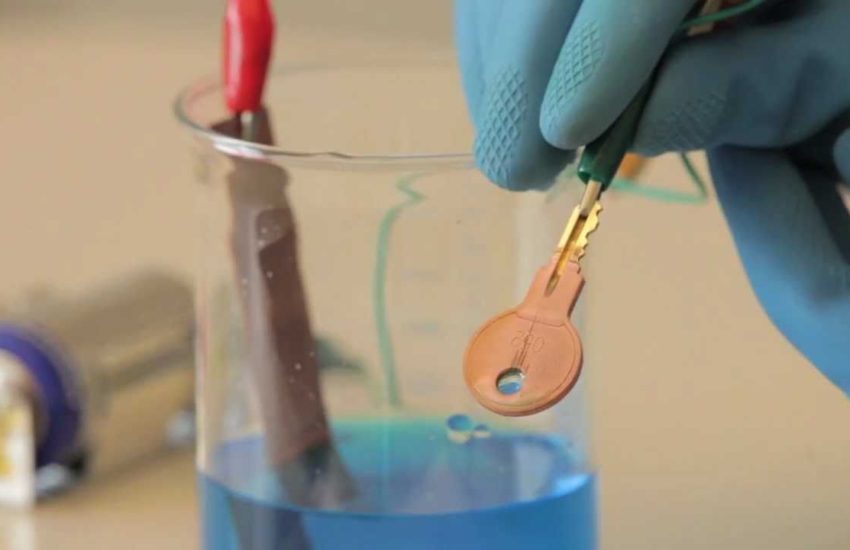

Electroplating

It is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating.

Electrostatic Painting

Electrostatic painting defines a paint application technique that is based on the concept that opposites attract

Hot Dip Galvanizing

When clean steel is immersed into molten zinc, a series of zinc-iron alloy layers are formed by a metallurgical reaction

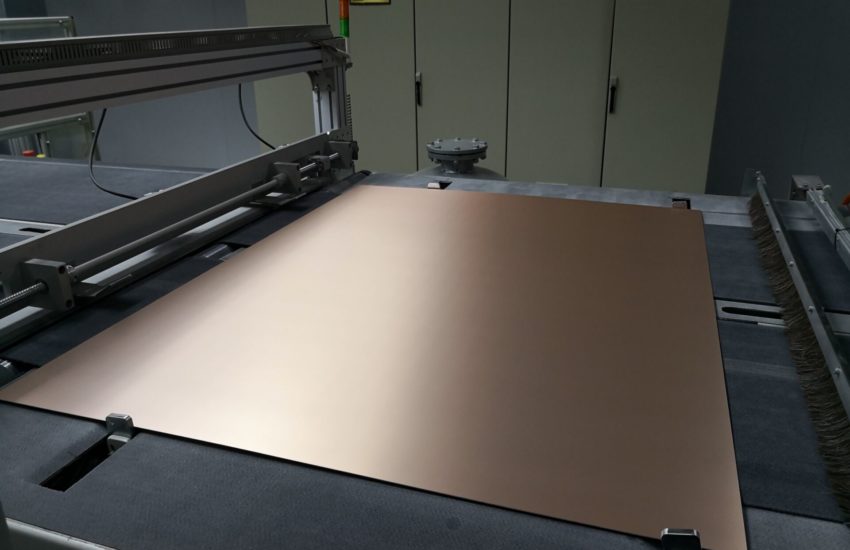

Lamination

The electrical equipment such as transformers and motors usually use a steel laminate to form the core of the coils.

Passivation

Passivation is the process of treating or coating a metal in order to reduce the chemical reactivity of its surface.

Power Coating

Powder may be thermoplastic or thermoset polymer. It is used to create a hard finish that is tougher than conventional paint

Spray Painting

Priming metal is important, as metal primer spray provides a surface that regular spray paint can then bond to.