Machining

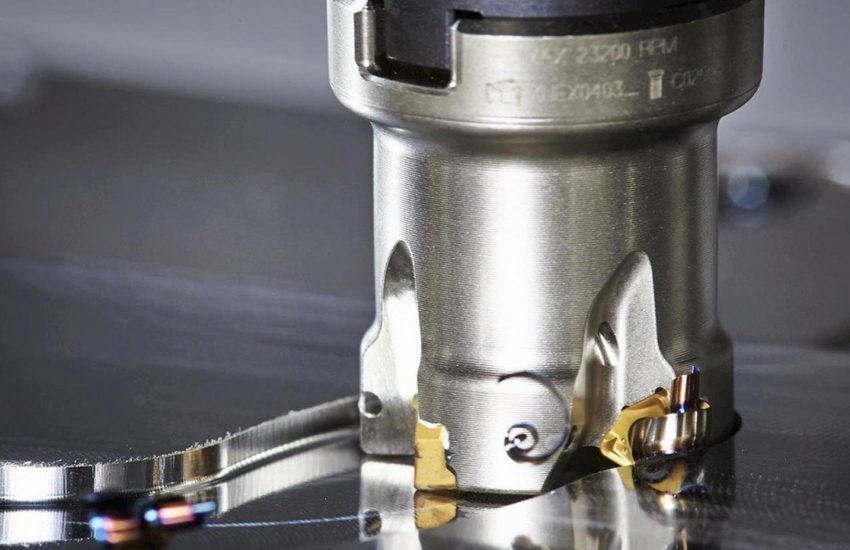

CNC & VMC Machining

It is a subtractive manufacturing process which typically employs computerized controls and machine tools.

Groove Cutting

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material

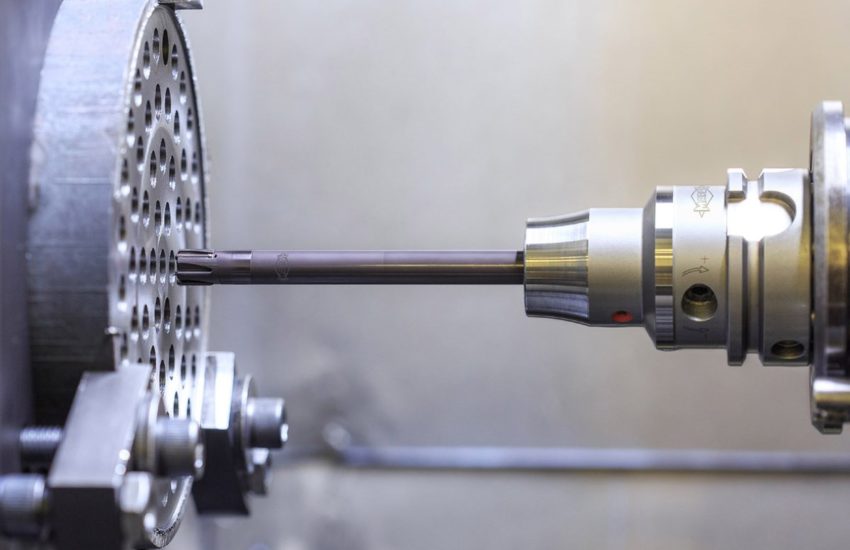

Shaping/ Forming

It is the metalworking process of fashioning metal parts and objects through mechanical deformation